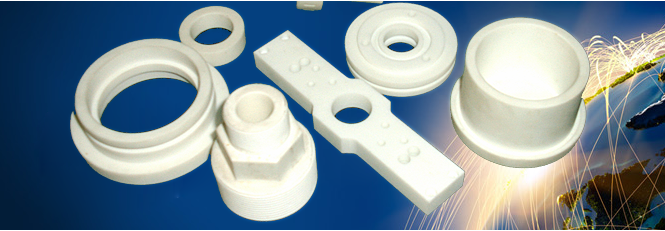

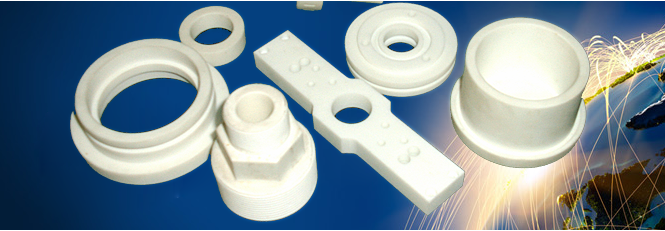

Machinable Glass Ceramic

-

Machinable Glass Ceramic properties

Machinable glass ceramics is a fluorophlogopite glass-ceramic with synthetic mica as the main crystal phase,the main component is fluorophlogopite (Mg3K[AlF2O(SiO3)3]). And the glass composition with silica as the main component . The material is similar to MACOR. The performance is basically the same.

Machinable Glass Ceramic have the following power feature:

a) Machinable with ordinary metal working tools.

b) Allows Fast Turnaround,no post firing required.

c) Holds Tight Tolerances, up to .0005"

d) Withstands High Temperature, up to 800℃

e) Clean, no outgasing and zero porosity

Physical Properties

Color

White

Density

2.48 g/cm3

Porosity

0.069%

Young’s Modulus

65 GPa @ 25C°

Rockwell Hardness A Scale

40

Modulus of Rupture

>108 MPa

Compressive Strength

>508 MPa

Impact toughness

>2.56KJ/ m2

Thermal Properties

Thermal Expansion

8.6 ppm @ 100 – 600C°

Thermal expansion coefficient

72×10-7/°C ( from -50°C to 200°C)

Thermal Conductivity

1.71 W-mk @ 25C°

Maximum No Load Temp.

1000C° Short Term

Maximum Long Term Temp.

800C° Continuous

Electrical Properties

Volume Resistivity

>1016 0hm-cm

Dielectric Strength

40 KV/mm– AC/DC @ 1mm

Loss Tangent

1-4 x 103 @ 1 KHz

7 x 103 @ 8.5 KHz

Dielectric constant

6-7

Volume resistance

1.08×1016Ω.cm

1.5×1012Ω.cm

1.1×109Ω.cm

Outgassing rate

room temperature

8.8×10-9 ml/s. cm2 Vacuum for 8 hours

Helium transmission rate

1×10-10ml/s (After burning at 500°C, cool to room temperature)

Gravimetric Weight Loss @ 95C°

Solution

Concentration

PH

Time

Weight Loss

Hydrochloric Acid

5 % HCl

0.1

24 hrs.

~0.26 mg/cm2

Hydrofluoric acid

5%HF

~83mg/ cm2

Sodium Carbonate

0.02 N Na2CO3

10.9

6 hrs.

~0.012 mg/cm2

Sodium Hydroxide

5% NaOH

13.2

6 hrs.

~0.85 mg/cm2